It’s a familiar sight: Steam is being used as a heat medium in many industrial facilities. For example industrial laundry facilities, paper and food plants – the typical vapor plume indicates the ongoing production. Everywhere steam is being blown in the atmosphere. Eventhough we all are aware that steam is so much more than hot air.

Laundry facility and dry cleaning service Klaiber, Vilingen-Schwenningen

Torsten Klaiber, Master Craftsman in Textile Cleaning, Certified Disinfector:

Before the conversion we used to work with a steam boiler 3t, year of construction 1968 and a conventional condensate system without utilization of the condensate.

Thursday the assembly work started at 2pm, installation of the new boiler in combination with the new condensate system steam x – module 1 + 2. Saturday at 6pm the system was ready for operation.

Why didn’t we do this much earlier? We save more than 14 % primary energy with steam x and the new boiler.

The investment practically pays for itself due to the energy savings.

16% energy loss

Conventional Systems need to discharge excess steam via the roof for pressure compensation. The energy for further utilization gets lost.

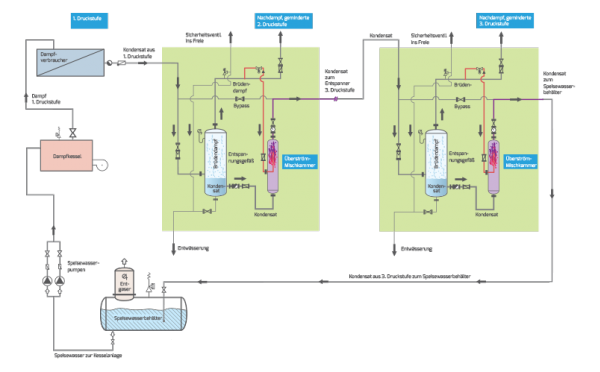

Steam X allows the residual steam to be harnessed within the system. All energy can be utilized. It can be exploited to heat up water in a laundry facility or to power a feed-water heating system. Steam X can be adjusted for all electrical consumers of different pressure types in numerous ways, so that optimal energy savings can be achieved.

Besides the usable energy, excess steam is being produced by every industrial facility, which is unexploitedly emitted as flash steam. But the steam contains valuable energy. That’s why we developed Steam X.

The patented vapor recovery system Steam X allows the excess steam to become utilizable again. Occuring flash steam is being brought back into the draining condensate and fed back repeatedly into the energy cycle. An open system is being turned into a closed system. Available energy can be used optimally – as far as heating the feed water and other electrical consumers.

The flow chart shows the structure and the components of steam X.

In vielen industriellen Anlagen entsteht überschüssige Energie, die als Nachdampf über Dach geht. Sie möchten diese Energie gern nutzen, können mit der Wärme aber nicht arbeiten?

Wir gewinnen aus Dampf Kälte. Mit dem patentierten Dampfrückgewinnungssystem steam x.

Ausgezeichnet mit dem Umweltpreis 2018 der Handwerkskammer Chemnitz.

Ausgezeichnet mit dem Bundespreis 2019 für hervorragende innovatorische Leistungen für das Handwerk